Thursday April 2, 2020 ~ VANCOUVER ISLAND

by Mary Brooke ~ West Shore Voice News

Let’s look at a a few things about ventilators for use against COVID-19 in BC hospitals: how many, what they do, how more could be manufactured locally.

Acute care of COVID-19 patients in hospitals usually (or ideally) requires use of a ventilator. The mechanical ventilator provides oxygen to the patient through a tube inserted down the windpipe or through an incision in the throat. The additional oxygen is for assisting the patient with breathing, as part of counteracting the attack by the COVID-19 virus in the bronchial tree within the lower lungs.

During the management of a patient’s COVID-19 infection in hospital, receiving oxygen in time (before there is too much respiratory cell damage) can be a matter of life or death.

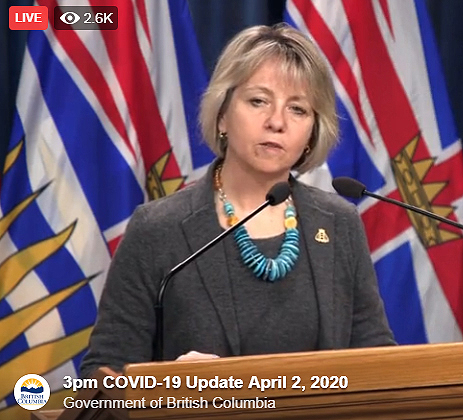

BC Provincial Health Officer Dr Bonnie Henry has said few times during her daily media teleconferences that ‘earlier intervention with a ventilator is better than later’ for ideal intervention of progressive COVID-19 disease.

Ventilators are used in intensive care units, hence now the daily counts of acute care bed availability among hospital bed tallies (as given in the daily briefings by BC Health Minister Adrian Dix and Dr Henry).

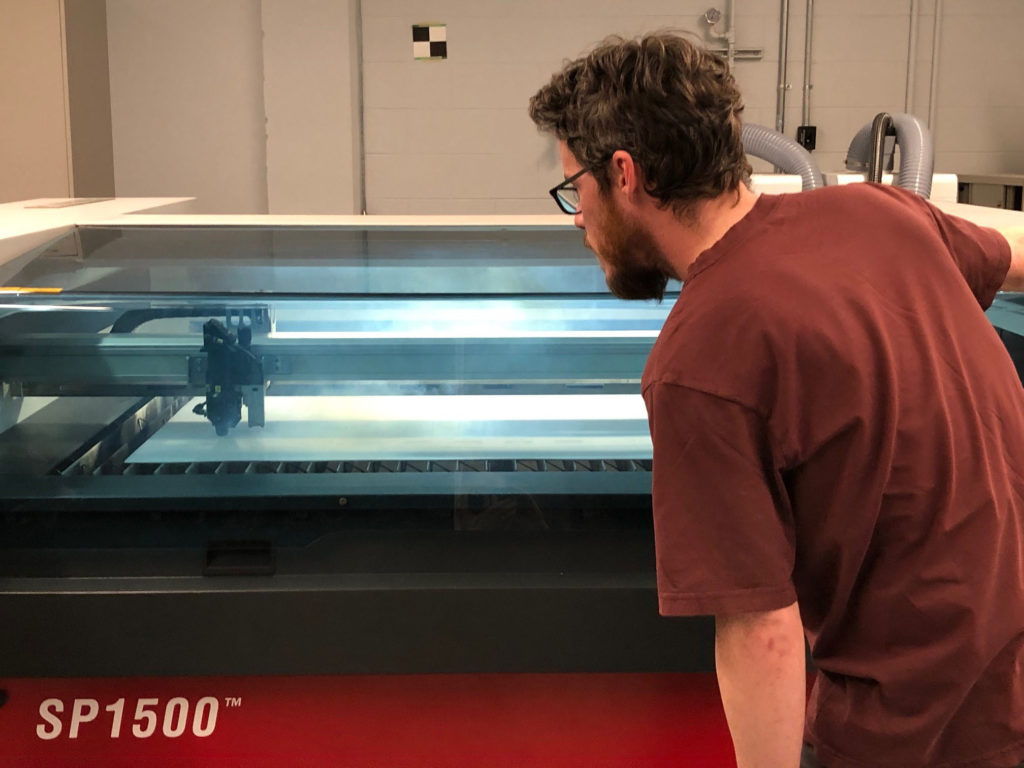

Just as the manufacture of guns, grenades and tanks during World War II was ramped up through the retooling of industry, the retooling of companies that produce various types of equipment and machines to instead produce ventilators could be a powerful shift in the now epic fight against COVID-19.

Ventilators are a suitably humble sort of equipment, in that they support a somewhat humble process called breathing. Humble but fundamental.

A ventilator is based on a relatively simple mechanical principle … transporting oxygen from a reservoir through a tube into the patient’s lungs, managed by a computerized regulating device. There is also the additional option for rejigging the standard ventilator with additional tubing and/or a 2-way or 4-way valve in order to serve multiple patients with one machine.

The adaptation of ventilators is already being done in other urgent care scenarios of COVID-19 including in Italy where a massive outbreak has killed 13,157 people so far. In the USA the death tally to date is 3,846 and in Canada 105. Globally the death count due to COVID-19 so far (as at April 2) is 45,525. [Those counts are from World Health Organization statistics as of 10 am Geneva time, or 1 am Pacific Time, April 2.]

A video online by a nurse who demonstrated her method for attaching the 4-way valve is being viewed by doctors in the USA as the pandemic impacts large portions of the United States (where the largest outbreak is presently in New York City, and where California and Florida have seen large outbreaks).

There is even a 9-way hack for ventilators. A few weeks ago, Elon Musk and others promptly started working on individual valve controls per patient so as to personalize care and avoid cross-flow risk. Musk wrote on his Twitter feed on March 20: “A single computer, pump & pressure accumulator would be fine for many patients, but ideally individual valves per patient to personalize care & avoid cross-flow risk.”

By March 31, Musk had Tweeted: “We have extra FDA-approved ventilators. Will ship to hospitals worldwide within Tesla delivery regions. Device & shipping cost are free. Only requirement is that the vents are needed immediately for patients, not stored in a warehouse. Please me (@elonmusk) or @Tesla know.”

In BC, at last official count there were 735 ventilators for use in the 19 primary care sites that will deal with COVID-19. That tally is comprised of 705 (as announced on Friday March 27 during a lengthy remote technical briefing for media) and 30 more announced March 31 by Health Minister Adrian Dix (15 of those new, and 15 refurbished).

Meanwhile, today Minister Dix said there are 4,273 “empty beds” available for COVID-19 patient care in 19 primary care hospital sites, which indicates the scope of how many more ventilators might be needed.

Those 4,273 empty across all health authorities/regions in BC, comprise 62.2% of hospital capacity (55.4% critical care capacity). “Both of those numbers are stable,” said Dix in his daily media briefing with Dr Henry.

There are more ventilators elsewhere in the system, dedicated for use at BC Children’s Hospital and BC Women’s Hospital in Vancouver; those are not directly included in the COVID-19 ventilator data count, explained Dix on March 27.

The federal government last week announced that it would partner with manufacturers and other businesses with technical equipment production capacity to help them retool to produce a range of necessary equipment in the fight against COVID-19, including personal protective equipment (aka PPE) such as N-95 masks, facial visors, gowns and gloves.

Right here on Vancouver Island, Camosun College’s applied research and innovation arm called Camosun Innovates has teamed up with local business AP Plastics to produce more than 9,000 medical grade face shields for local health care workers on the front lines of the global pandemic.

Perhaps there are small machine-shops (presently for vehicle repairs or boat manufacture, for example) that could redeploy their shops and retrain their personnel to produce ventilators. Ventilators, at their core, are simply a type of pump, but obviously with standardized controls for use in a medical setting.

On the subject of adapting existing ventilators with valves in order to supply multiple patients with oxygen, today the BC Health Ministry issued this statement to West Shore Voice News:

“The total count of ventilators that has been shared in briefings is based on the physical machines and does not include any potential expansion capacity for supporting more than one patient with a tube or T-shaped valve. We do not have information available to share on how ventilator modifications, or T-valves, would increase our capacity at this time.”